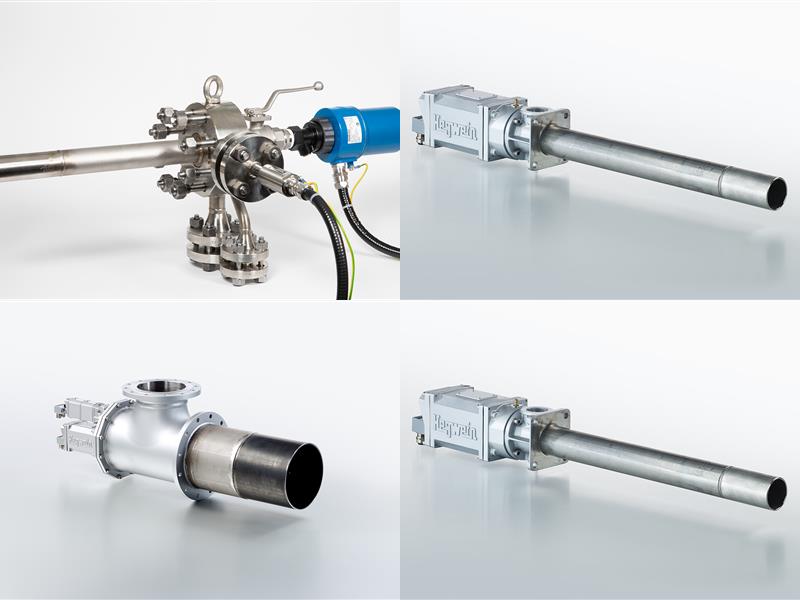

Valve system contains;

001 Swivel fitting B29148 2pcs

Origin Com. 205.2796

Designation data

Design data

Crowd

Supply air 4.0 bar

DeltaP 16.0 bar

Test pressure passage standard 6 bar

Medium Not specified

Temperature °C No information

How Fail Close works

Drive position A1 (Pfeiffer standard)

001.001 k14b3061b63 2 pcs

BR14b DN80 PN40

B1 R20 WTD Lug HSB7

Control or butterfly valve, double eccentric, end fitting

Case: 1.4408

Slice: 1.4408

Shift shaft: 1.4542/H1150

Storage: 1.4571/HSB7

Seat ring: PTFE seal ring/spring loaded

Housing seal: PTFE

Shaft seal: disc spring-loaded

PTFE roof boot packing

Version: TA-Luft

continuous sealing strip

Flange sealing strip: EN 1092-1 Form B1

Length: EN 558 R20 (46mm)

DIN / ISO 5211: F05 / SW 14

MD Max at 20°C [Nm]: 592

PS(1) / TS(1) 40bar (-60C)

PS(2) / TS(2) 40bar (50C)

PT [bar]: 63

TS Min [°C]: -60

TS Max [°C]: 200

001.002 36000 2 pcs

Strength and leak testing

PED 2014/68/EU + AD2000-A4

Test basis: DIN EN 12266-1

Device design: DIN 3354 flaps + DIN 3230 part 3; Direction:

on the rule side

Strength test: DIN EN 12266-1 P10 (see test instructions)

Leak test: DIN EN 12266-1 P11 (see test instructions)

Seat tightness: DIN EN 12266-1 P12 (see test instructions)

Leak rate: A

001.003 43643fc 2 pcs

SRP00220-4.0 F10-VK22

BR31a Standard FC

Pfeiffer double piston swivel drive

Version: BR31a standard

Housing: aluminum; ALODUR

Size: 220

DIN 5211 flange: F10

Shaft holder: VK22 - internal square 22mm diagonal

Swivel angle: 90° +5°/-15° in both end positions

Mode of action: single-acting

Number of springs: 4+4

Spring rotation direction: CW – clockwise

Safety position: Closed

Pneumatic connection: NAMUR 24x32mm; G1/4“

VDI/VDE3845 Level 1: AA2 (80x30x30)

Perm. Ambient temperature: -40°C…+80°C

Including blowout-proof end stops and integrated centering ring

001.004 ms14b0008 2 pcs

Mounting kit F10/F05-D22/H14

BR14b DN80/100; CS; 1.4305; A4-70

BR/CS-F10/F05-D22/H14-C4-A1

BR/CS console 1.0038 hot-dip galvanized

F10/F05 Drive side F10

Fitting side F05

D22/H14 coupling 1.4305

Drive side 22mm diagonal external square

Fitting side 14mm internal two-flat

C4 - A1 Corrosivity category C4 / requirement class A1

Screws A4-70

001.005 30600 2 pcs

Attachment of the swivel drive

F10

001.006 408182

3730-3-110010400001001001009997

e/p positioner TROVIS 3730 HART

Ex approval and marking II 2 G Ex ia IIC T4/T6 Gb / II 2D Ex ia IIIC T85 °C

Db, BVS 18 ATEX E 044 X; Slot A: position indicator 4 to 20 mA; Slot C: 2 inductive

Limit contacts SJ2-SN, NC (NAMUR) and binary output (NAMUR); Electrical

Connection 2-fold M20 x 1.5, 1 cable gland; SIL; Hardware version 1.00.00;

Software version V2.00.15;

Variant ID: 100132249/100132248

001.007 46424

Heavy attachment kit 3730 on drive, AA1-AA4

VDI/VDE 3845; 90°, for BR31a 15-5000

Attachments to part-turn drives VDI/VDE 3845 (for

all dimensions of level 1 / 2009), heavy version

Variant ID: 1400-9244

001.008 44198

Connection plate 3730/3766 aluminum

G1/4"; for free piping

Connection plate 3730/3766

Aluminum G1/4"

Variant ID: 1400-7461

001.009 30581

Mounting positioner

001.010 b0001316

Piping 2 components V4A 8mm

Ermeto

Complete piping of 2 components

Material:

- Ermeto stainless steel screw connections

- Tube Ø 8mm stainless steel

001.011 34001

Inspection certificate 3.1

according to DIN EN 10204

accordingly

Pressure Equipment Directive 2014/68/EU and

the AD-2000 leaflets

Exams:

Dimensional testing, strength testing,

Leak test, functional test

001.012 34003

Material acceptance test certificate 3.1

according to DIN EN 10204

accordingly

Pressure Equipment Directive 2014/68/EU

Materials in accordance with EN standards

and AD 2000 information sheets

![Valve system contains; 001 Swivel fitting B29148 2pcs

Origin Com. 205.2796

Designation data

Design data

Crowd

Supply air 4.0 bar

DeltaP 16.0 bar

Test pressure passage standard 6 bar

Medium Not specified

Temperature °C No information

How Fail Close works

Drive position A1 (Pfeiffer standard)

001.001 k14b3061b63 2 pcs

BR14b DN80 PN40

B1 R20 WTD Lug HSB7

Control or butterfly valve, double eccentric, end fitting

Case: 1.4408

Slice: 1.4408

Shift shaft: 1.4542/H1150

Storage: 1.4571/HSB7

Seat ring: PTFE seal ring/spring loaded

Housing seal: PTFE

Shaft seal: disc spring-loaded

PTFE roof boot packing

Version: TA-Luft

continuous sealing strip

Flange sealing strip: EN 1092-1 Form B1

Length: EN 558 R20 (46mm)

DIN / ISO 5211: F05 / SW 14

MD Max at 20°C [Nm]: 592

PS(1) / TS(1) 40bar (-60C)

PS(2) / TS(2) 40bar (50C)

PT [bar]: 63

TS Min [°C]: -60

TS Max [°C]: 200

001.002 36000 2 pcs

Strength and leak testing

PED 2014/68/EU + AD2000-A4

Test basis: DIN EN 12266-1

Device design: DIN 3354 flaps + DIN 3230 part 3; Direction:

on the rule side

Strength test: DIN EN 12266-1 P10 (see test instructions)

Leak test: DIN EN 12266-1 P11 (see test instructions)

Seat tightness: DIN EN 12266-1 P12 (see test instructions)

Leak rate: A

001.003 43643fc 2 pcs

SRP00220-4.0 F10-VK22

BR31a Standard FC

Pfeiffer double piston swivel drive

Version: BR31a standard

Housing: aluminum; ALODUR

Size: 220

DIN 5211 flange: F10

Shaft holder: VK22 - internal square 22mm diagonal

Swivel angle: 90° +5°/-15° in both end positions

Mode of action: single-acting

Number of springs: 4+4

Spring rotation direction: CW – clockwise

Safety position: Closed

Pneumatic connection: NAMUR 24x32mm; G1/4“

VDI/VDE3845 Level 1: AA2 (80x30x30)

Perm. Ambient temperature: -40°C…+80°C

Including blowout-proof end stops and integrated centering ring

001.004 ms14b0008 2 pcs

Mounting kit F10/F05-D22/H14

BR14b DN80/100; CS; 1.4305; A4-70

BR/CS-F10/F05-D22/H14-C4-A1

BR/CS console 1.0038 hot-dip galvanized

F10/F05 Drive side F10

Fitting side F05

D22/H14 coupling 1.4305

Drive side 22mm diagonal external square

Fitting side 14mm internal two-flat

C4 - A1 Corrosivity category C4 / requirement class A1

Screws A4-70

001.005 30600 2 pcs

Attachment of the swivel drive

F10

001.006 408182

3730-3-110010400001001001009997

e/p positioner TROVIS 3730 HART

Ex approval and marking II 2 G Ex ia IIC T4/T6 Gb / II 2D Ex ia IIIC T85 °C

Db, BVS 18 ATEX E 044 X; Slot A: position indicator 4 to 20 mA; Slot C: 2 inductive

Limit contacts SJ2-SN, NC (NAMUR) and binary output (NAMUR); Electrical

Connection 2-fold M20 x 1.5, 1 cable gland; SIL; Hardware version 1.00.00;

Software version V2.00.15;

Variant ID: 100132249/100132248

001.007 46424

Heavy attachment kit 3730 on drive, AA1-AA4

VDI/VDE 3845; 90°, for BR31a 15-5000

Attachments to part-turn drives VDI/VDE 3845 (for

all dimensions of level 1 / 2009), heavy version

Variant ID: 1400-9244

001.008 44198

Connection plate 3730/3766 aluminum

G1/4"; for free piping

Connection plate 3730/3766

Aluminum G1/4"

Variant ID: 1400-7461

001.009 30581

Mounting positioner

001.010 b0001316

Piping 2 components V4A 8mm

Ermeto

Complete piping of 2 components

Material:

- Ermeto stainless steel screw connections

- Tube Ø 8mm stainless steel

001.011 34001

Inspection certificate 3.1

according to DIN EN 10204

accordingly

Pressure Equipment Directive 2014/68/EU and

the AD-2000 leaflets

Exams:

Dimensional testing, strength testing,

Leak test, functional test

001.012 34003

Material acceptance test certificate 3.1

according to DIN EN 10204

accordingly

Pressure Equipment Directive 2014/68/EU

Materials in accordance with EN standards

and AD 2000 information sheets](/image122/box.png)